Description

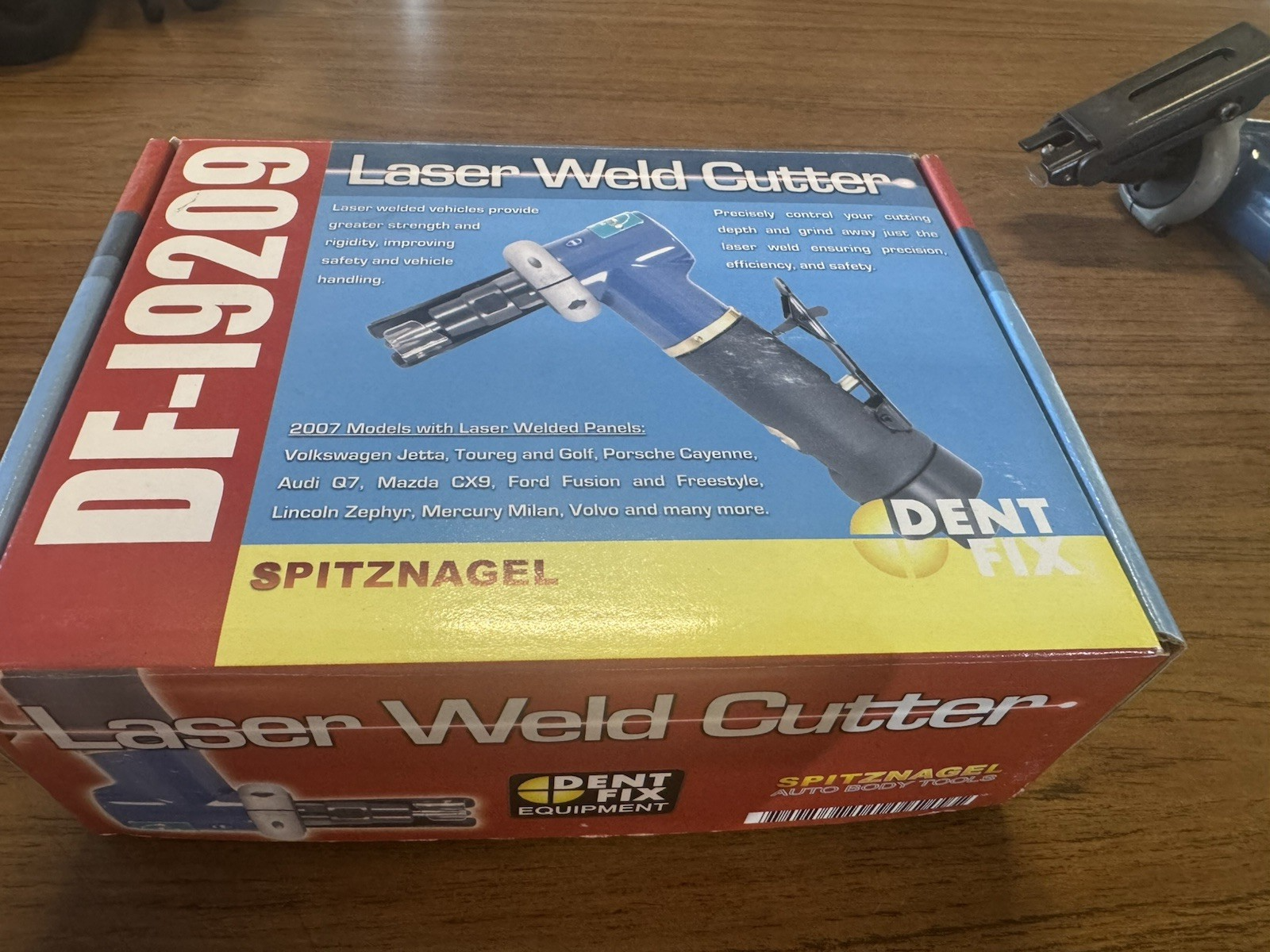

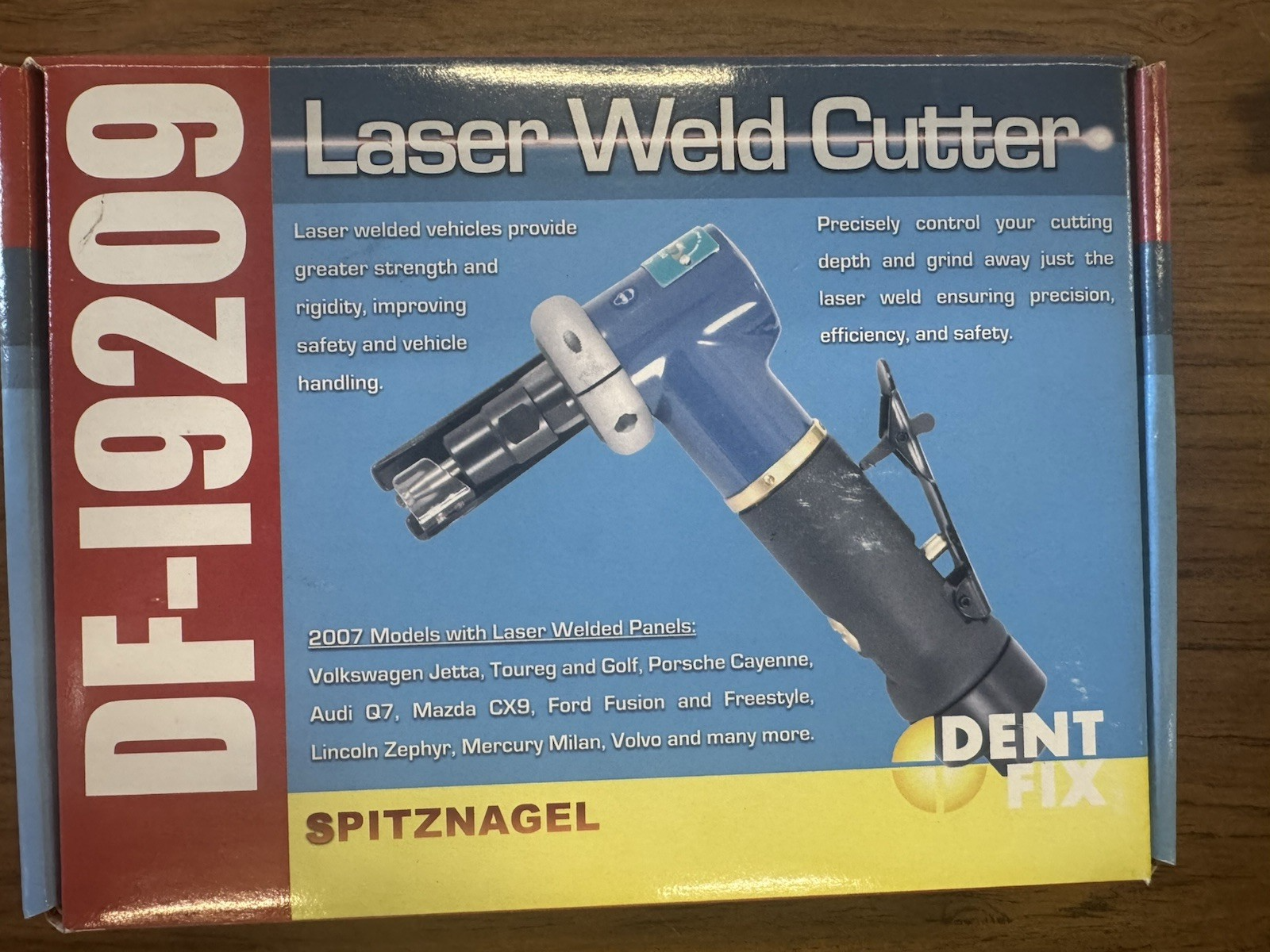

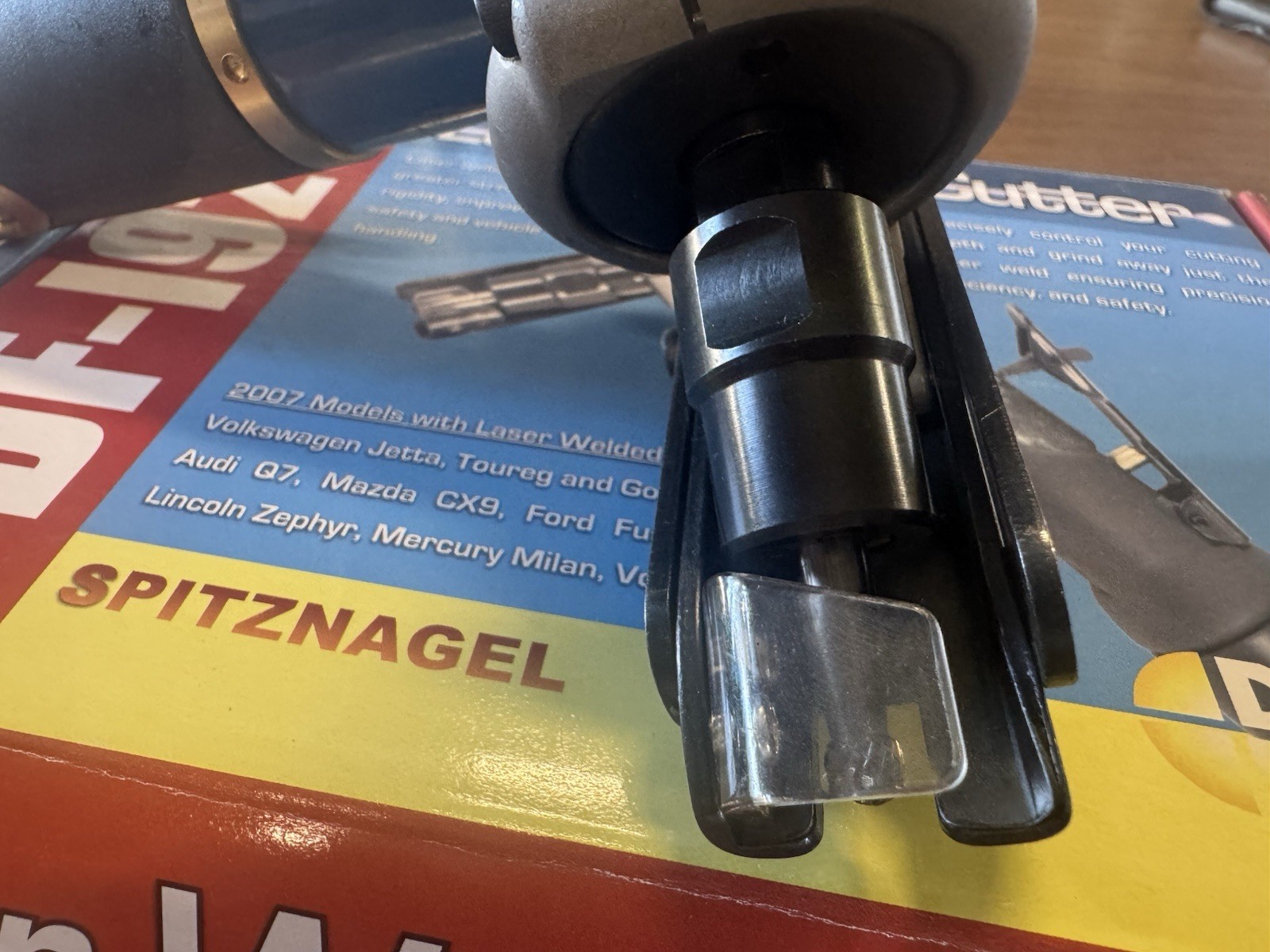

Spitznagel DF-I9209 Laser Weld Cutter

Features and benefits:

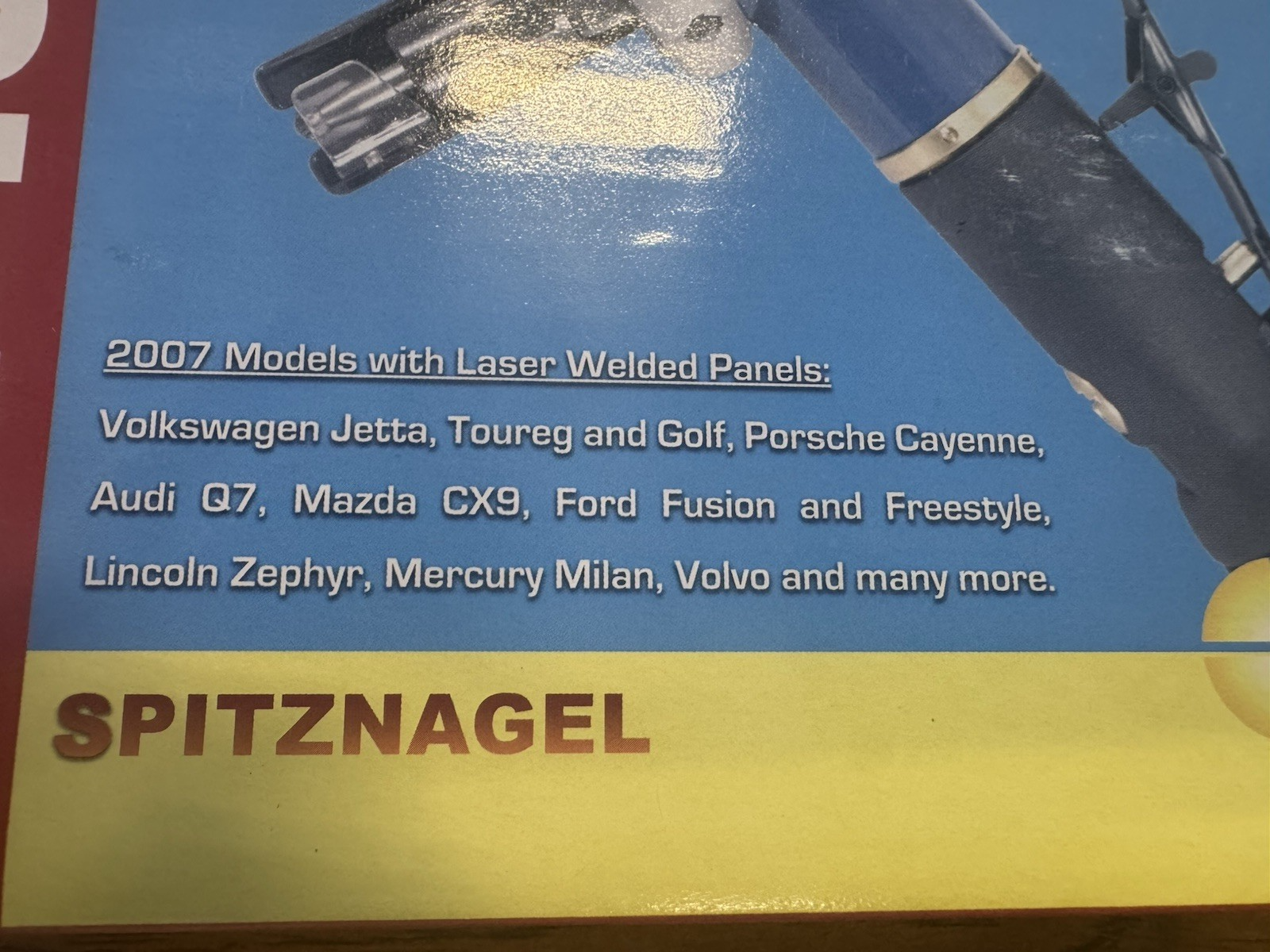

A laser weld cutter, Dent Fix DF-i9209 is a specialized tool used to precisely remove spot welds, particularly in automotive repair where laser welding is increasingly common. It’s designed for accuracy and efficiency when working with laser-welded panels, minimizing damage to surrounding materials during dent repair or panel replacement. Here’s a more detailed breakdown:

What it does:

-

The primary function is to cleanly separate panels joined by laser welding, a process gaining popularity in modern vehicle manufacturing

-

Precision Cutting:

-

Laser weld cutters offer controlled depth and accuracy, allowing technicians to remove the weld without harming the surrounding metal.

-

Repair and Panel Replacement:

-

This tool is crucial for dent repair, especially in areas with laser welds, and for replacing damaged panels that are laser-welded in place.

-

Reduced Damage:

-

By precisely removing the weld, the tool minimizes the need for grinding or excessive cutting, which can distort or damage the surrounding metal

-

Key Features and Benefits:

-

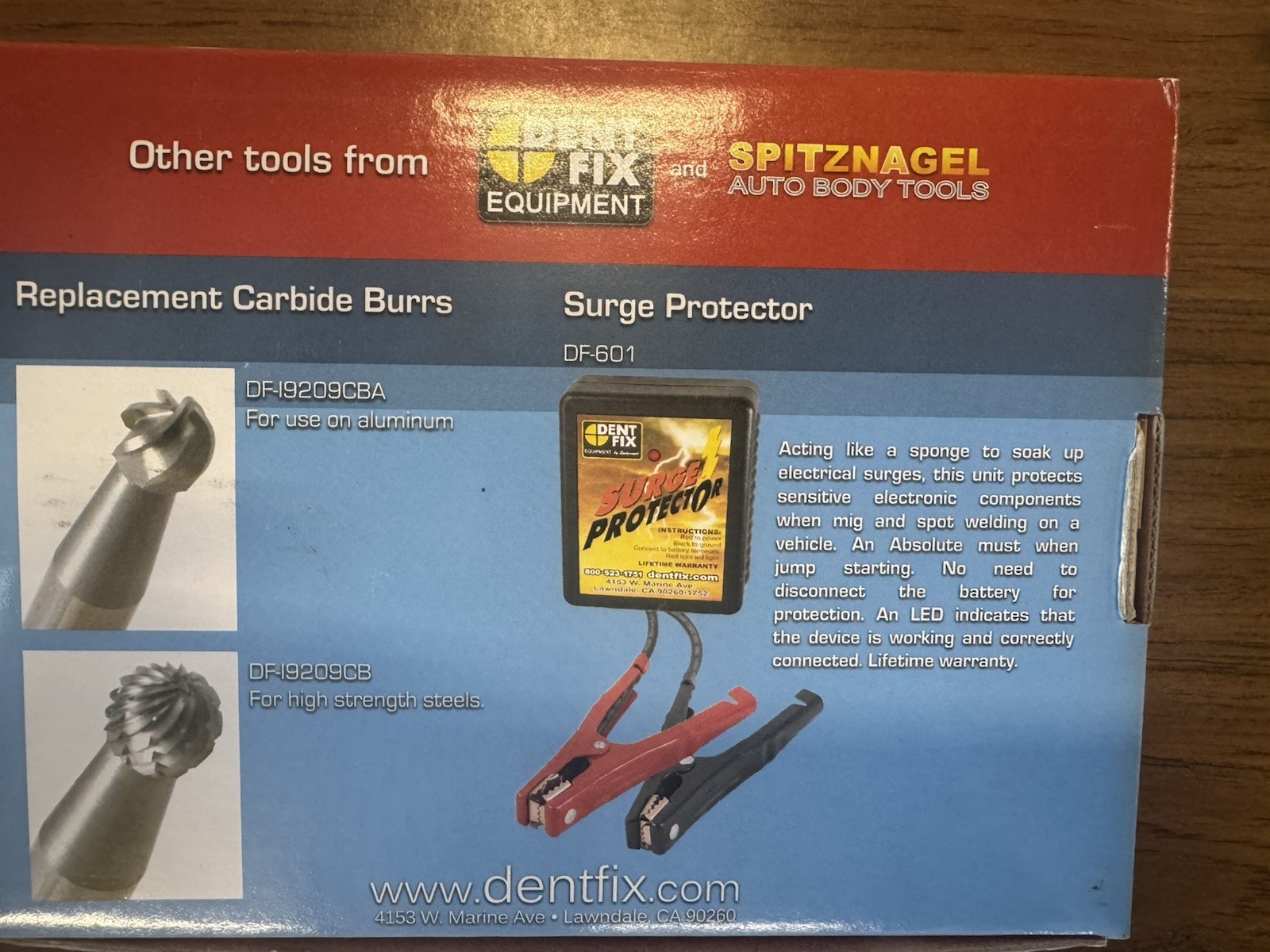

A carbide burr cutting bit is a key component, specifically designed for cutting through laser welds in steel or aluminum.

-

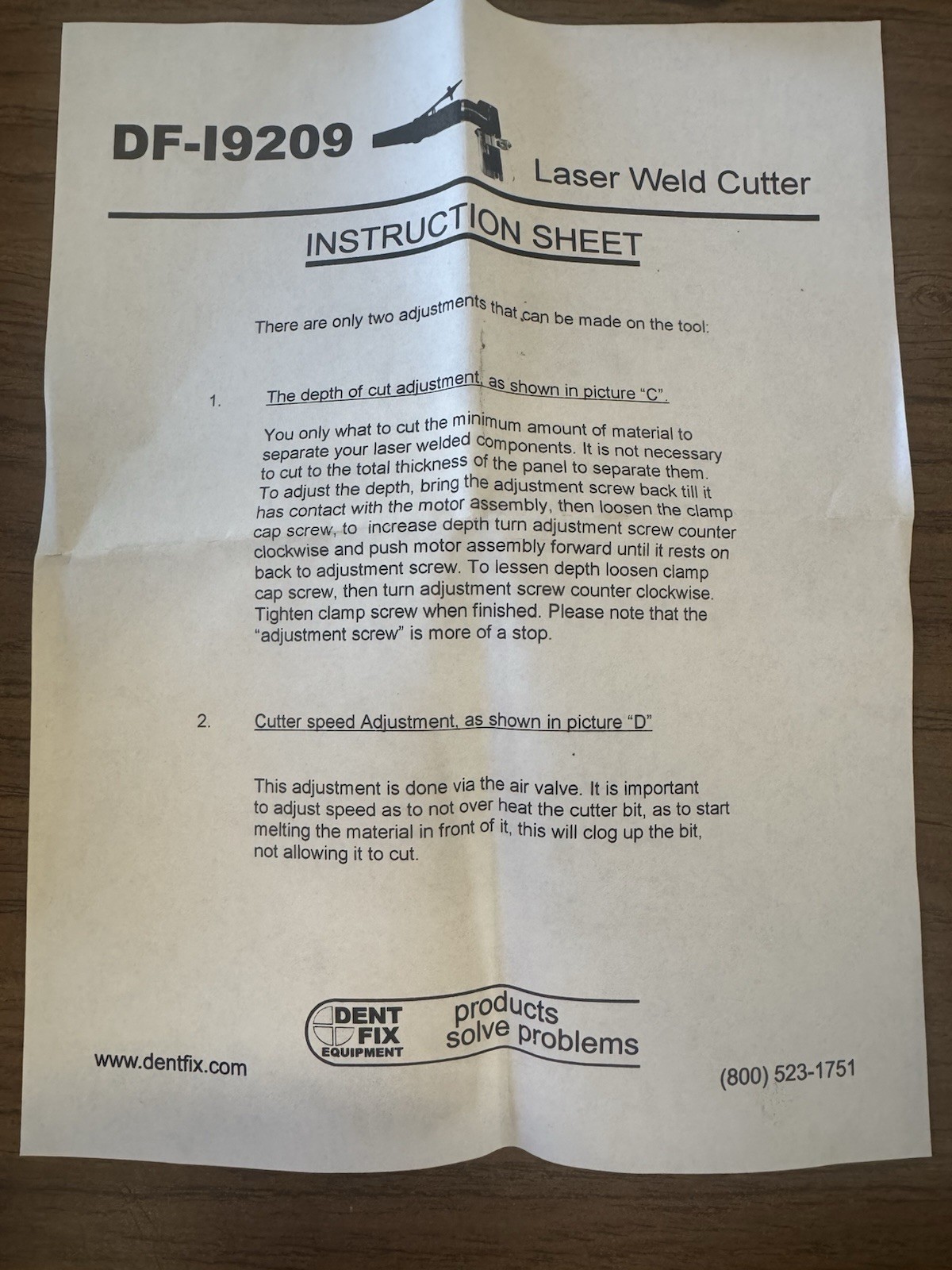

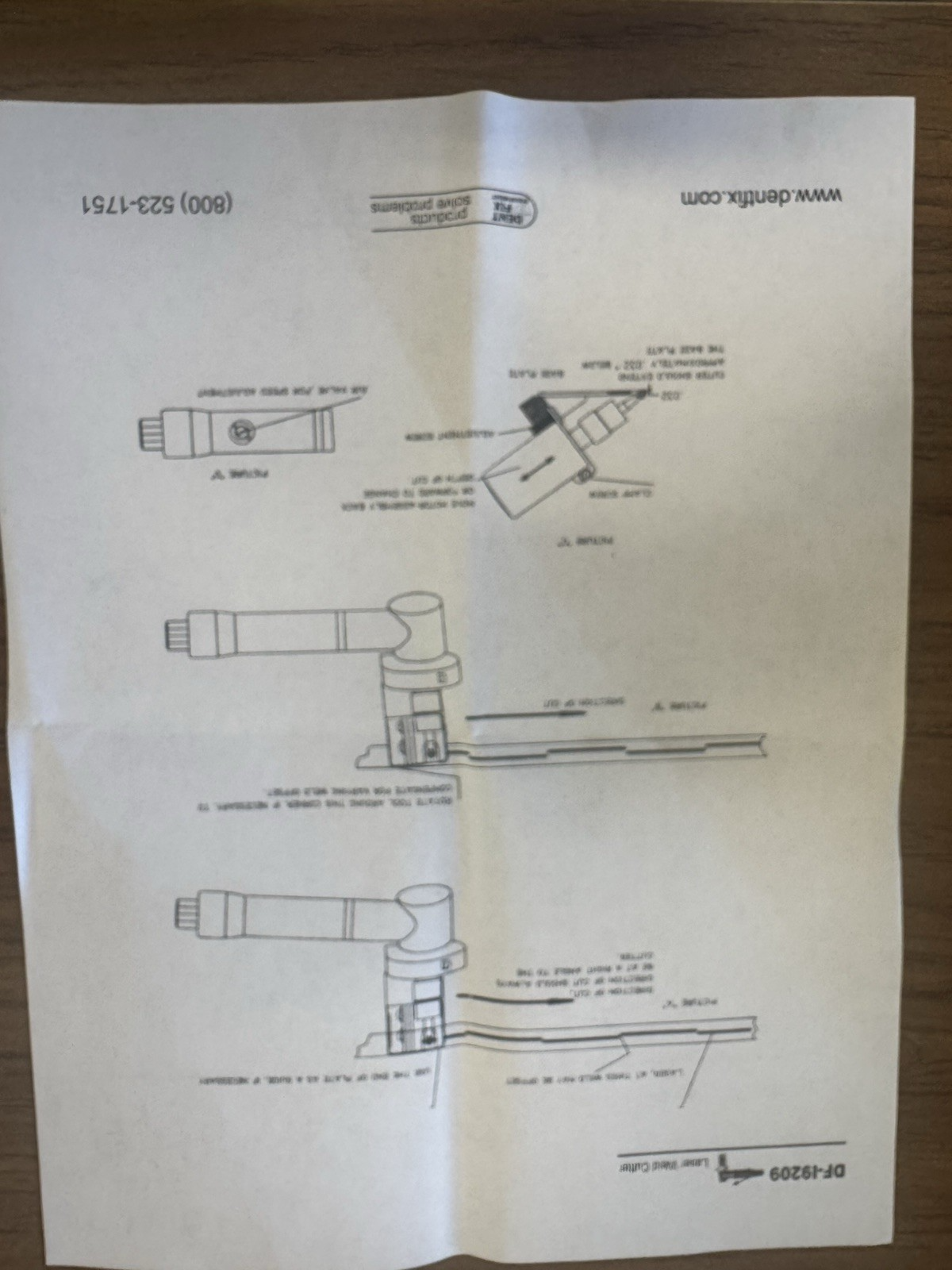

Controlled Cutting Depth:

-

This allows for removal of the weld without cutting into the underlying metal.

-

Efficiency:

-

The tool is designed to speed up the process of removing welds compared to traditional methods.

-

Ergonomic designs and features like pneumatic pressure (in some models) make the tool easier and safer to operate

-

Durability:

-

Built for long-term use in demanding environments like auto body shops. In the context of dent repair:

- The laser weld is carefully cut using the laser weld cutter.

- The damaged panel can then be removed.

- A new panel can be installed and welded into place.

- The area is then finished for a smooth repair.